MIT researchers have created a portable chip-based laser device that can instantly identify chemicals with unprecedented accuracy –– a breakthrough that could transform environmental monitoring and industrial safety.

The technology, published in the Light: Science & Applications journal on August 19, uses an ultrabroadband infrared frequency comb –– sometimes called an ‘optical comb’ –– to detect and distinguish trace compounds by measuring their unique light frequencies. In contrast to conventional spectrometers that require large equipment, the MIT technology combines all the necessary parts into a single chip, making it portable and suitable for distant environmental monitoring.

The research was led by Qing Hu, professor of electrical engineering and computer science at MIT. The research team focused on solving dispersion issues that have historically limited the bandwidth of frequency combs. Dispersion causes irregular spacing of laser lines, obstructing the creation of accurate frequency combs necessary for precise chemical detection.

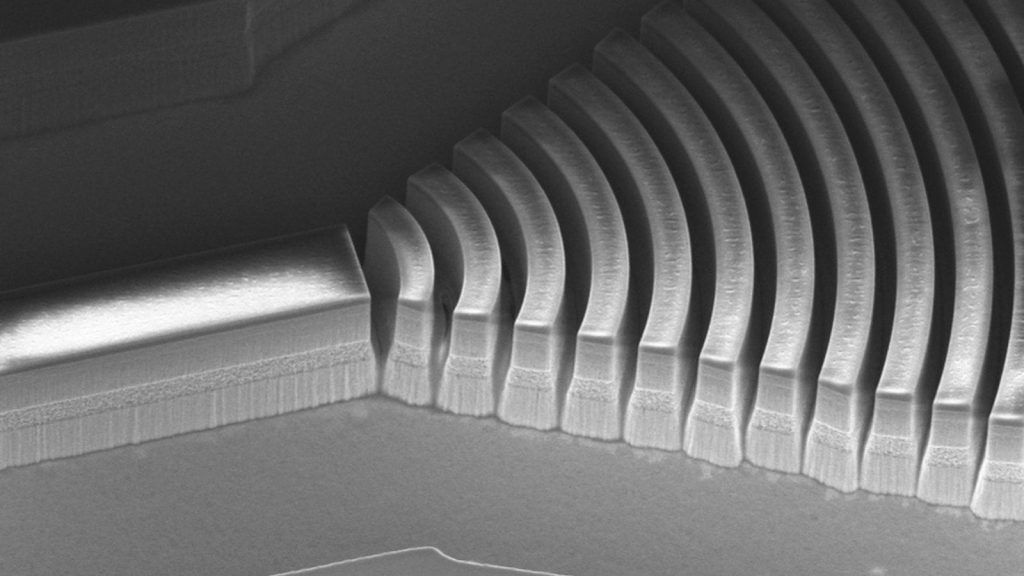

The breakthrough was inspired by their earlier work with terahertz frequency combs, where they used double-chirped mirrors (DCMs) for dispersion compensation. However, adapting this technology to infrared wavelengths posed significant challenges, as infrared waves are ten times shorter than terahertz waves, demanding extreme fabrication precision.

Challenges

Lead author Tianyi Zeng, who recently earned his PhD at MIT, described the manufacturing difficulties: “The adjacent layers of mirror differ only by tens of nanometres. That level of precision precludes standard photolithography techniques. On top of that, we still had to etch very deeply into the notoriously stubborn material stacks.”

After over two years of development and nearly abandoning the project, the team realised they could employ a standard DCM design compatible with infrared radiation, since infrared sources are less lossy than terahertz lasers. By creating an on-chip dispersion measurement platform, they were able to successfully incorporate the mirror directly onto the laser, eliminating the need for large external equipment.

What lies ahead

This technology promises more precise environmental sensors capable of distinguishing multiple hazardous substances from trace air gases. Researchers can utilise this versatile method to evaluate dispersion and develop compensating DCMs for various laser platforms, potentially leading to combs with even greater bandwidth and power for demanding applications. This study marks a significant step towards mass-produced remote sensors that could transform chemical detection in industrial safety and environmental monitoring.

Expand

© IE Online Media Services Pvt Ltd