In the fight for more sustainable manufacturing processes, a team from MIT’s Computer Science and Artificial Intelligence Laboratory and the Hasso Plattner Institute has developed SustainaPrint. This new approach to 3D printing is shaking up how we think about the trade-offs between environmental impact and material durability. Chuck Hull, who invented stereolithography in 1983, might not have envisioned this evolution, but his pioneering work set the stage for such innovations.

Typical biodegradable filaments are great for the planet, but less great when it comes to handling stress. They crack under pressure, quite literally. Looking to balance sustainability with strength, researchers crafted a method that uses just enough of the strong stuff to reinforce weaker, eco-friendly materials where it matters. Working with a 20 percent reinforcement threshold, the team found they could retain up to 70 percent of the strength relative to objects printed entirely with high-performance plastics, said MIT PhD student Maxine Perroni-Scharf, a lead author on the project, according to a statement obtained by MIT News.

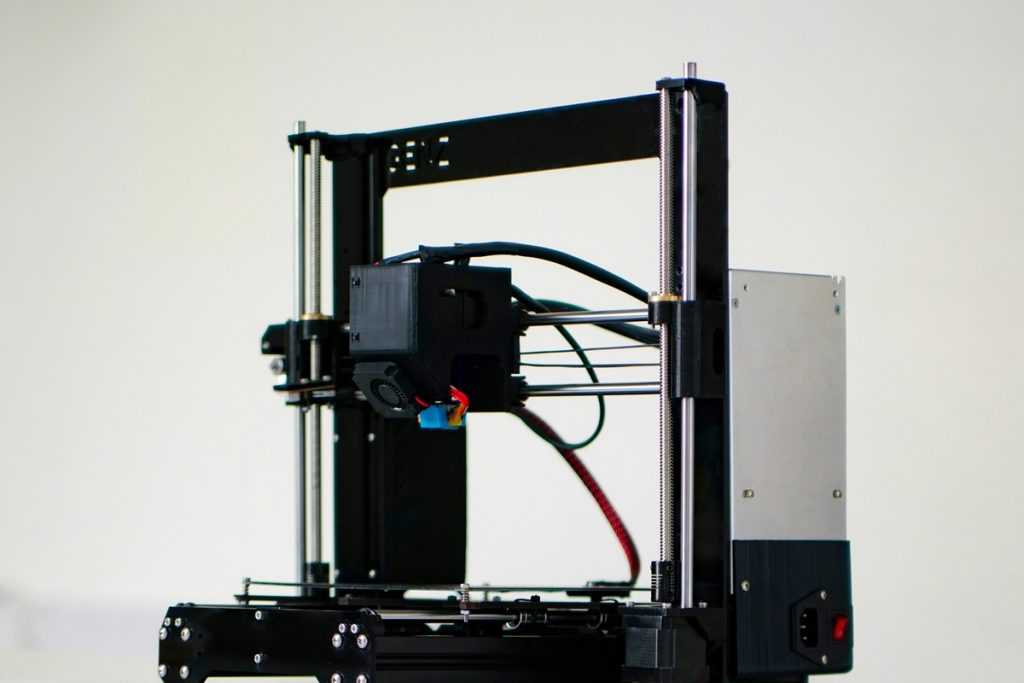

But how does this toolkit work? SustainaPrint starts by analyzing a 3D model’s stress points via finite element analysis simulations. Once the system identifies where the stress party’s at, it sends in reinforcements—namely, stronger material—to just those zones, leaving the rest of the object to be printed with the green goods. Their experiments included everyday items like headphone stands and wall hooks, each time comparing the resilience of parts printed solely with eco-friendly filament, standard PLA, and the SustainaPrint combo.

And for those without access to fancy testing gear, the researchers have thought one step ahead, creating a DIY toolkit that’s 3D-printable itself. This add-on helps users check a filament’s robustness using common home gym equipment, like pull-up bars or digital scales. It’s an affordable and low-barrier solution to quantifying strength before hitting the print button. Recognizing the potential for growth, the team envisions further software refinements and possibly incorporating AI to automate the process further. As Prof. Patrick Baudisch from the Hasso Plattner Institute points out, “Maxine presents the missing link between the theoretical/abstract idea of 3D printing material recycling and what it actually takes to make this idea relevant,” according to a MIT News article.