Most importantly, though, it scaled really well.

Economy of scale

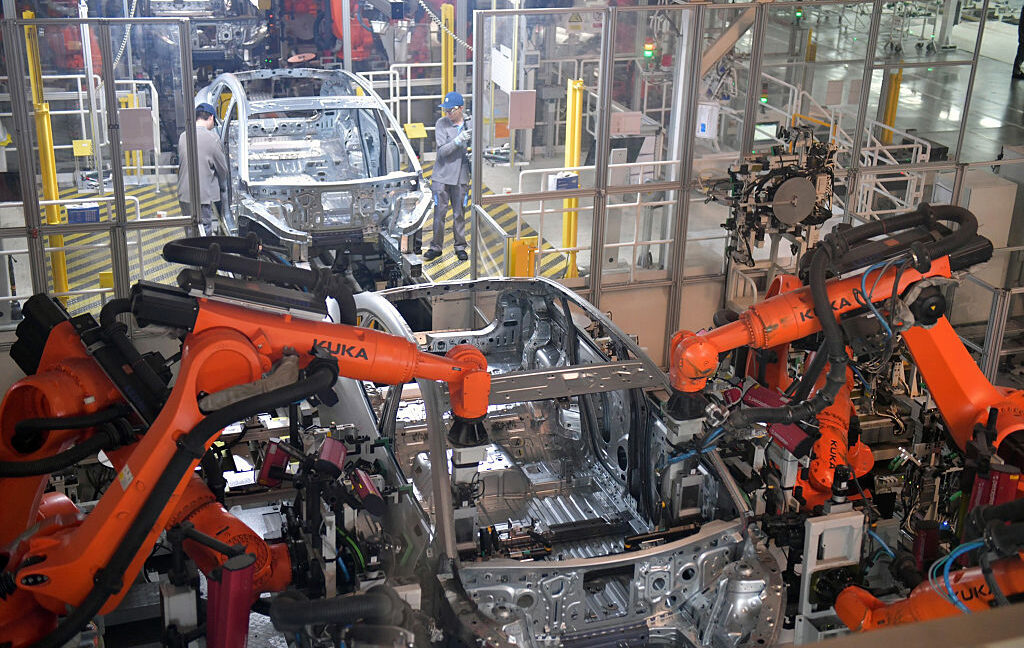

The problem with applying traditional computational methods to complex problems like managing robots at a factory is that the challenge of computation grows exponentially with the number of items you have in your system. Computing the most optimal trajectories for one robot is relatively simple. Doing the same for two is considerably harder; when the number grows to eight, the problem becomes practically intractable.

With RoboBallet, the complexity of computation also grew with the complexity of the system, but at a far slower rate. (The computations grew linearly with the growing number of tasks and obstacles, and quadratically with the number of robots.) According to the team, these computations should make the system feasible for industrial-scale use.

The team wanted to test, however, whether the plans their AI was producing were any good. To check that, Lai and his colleagues computed the most optimal task allocations, schedules, and motions in a few simplified work cells and compared those with results delivered by RoboBallet. In terms of execution time, arguably the most important metric in manufacturing, the AI came very close to what human engineers could do. It wasn’t better than they were—it just provided an answer more quickly.

The team also tested RoboBallet plans on a real-world physical setup of four Panda robots working on an aluminum workpiece, and they worked just as well as in simulations. But Lai says it can do more than just speed up the process of programming robots.

Limping along

RoboBallet, according to DeepMind’s team, also enables us to design better work cells. “Because it works so fast, it would be possible for a designer to try different layouts and different placement or selections of robots in almost real time,” Lai says. This way, engineers at factories would be able to see exactly how much time they would save by adding another robot to a cell or choosing a robot of a different type. Another thing RoboBallet can do is reprogram the work cell on the fly, allowing other robots to fill in when one of them breaks down.