Designing robot hardware is complex and slow because it involves many technical areas like motion, materials, and construction. While approaches like bio-inspired and soft robots have advanced the field, they still require lots of time and expert effort. To speed things up, researchers now use sampling-based design methods that quickly test many options using simulations, making it easier to find better designs faster.

Sampling-based robot design methods are fast and flexible, but they have some limitations, especially when it comes to making sure the designs can actually be built. These methods often struggle to account for real-world challenges like assembly requirements, traditional manufacturing tools, and the lack of detailed datasets.

To solve this, the researchers developed a new robot design framework using diffusion models (a type of advanced AI). This approach blends the strengths of traditional design—guided by human expertise—with AI-driven optimization.

The result? Robots that aren’t just theoretically cool but can be built straight off the design with no extra tweaking needed.

MIT’s CSAIL has developed a new design approach using diffusion-based AI models that can enhance human-created robots. Users upload a 3D robot design and mark the parts they want modified. The AI called GenAI then explores and tests new shapes for those parts through simulation. Once it finds the best design, users can directly 3D print a real-world robot—no extra edits needed.

An insect-sized jumping robot navigates rough terrains and carries heavy payloads

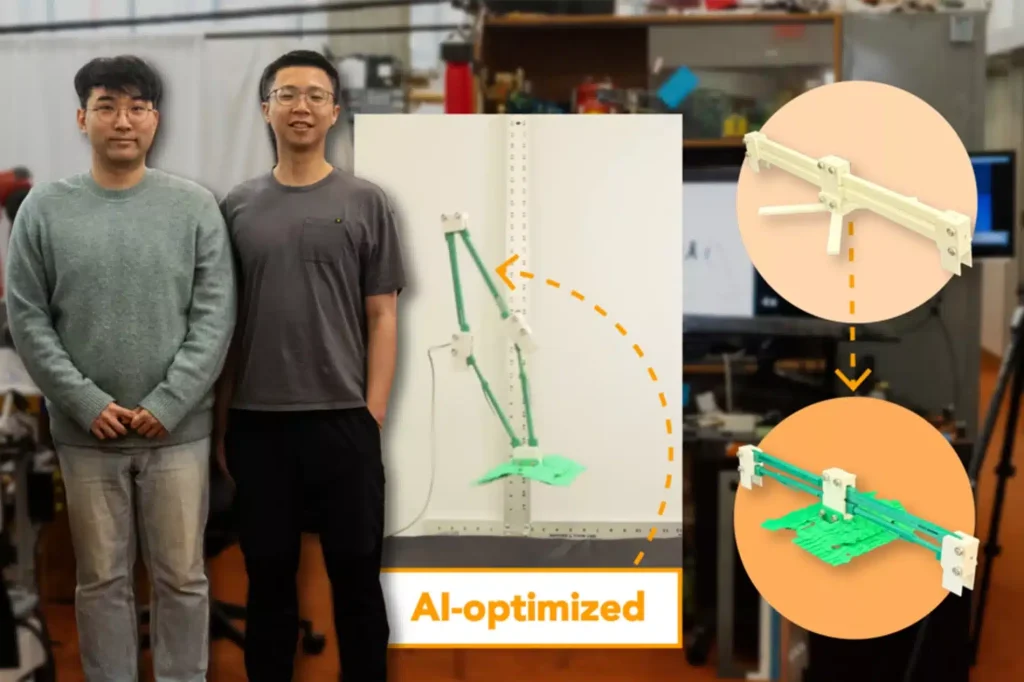

Researchers used AI to design a robot that jumps about 2 feet high, 41% higher than a similar robot they made without AI. At first glance, both robots look the same: made from the same plastic and shaped like flat panels that pop into a diamond shape when a motor pulls on them.

But here’s the difference: the AI-designed robot has curved joints—shaped kind of like drumsticks—while the human-made version uses straight, blocky pieces. That small design change helped the AI robot jump much higher using the same materials.

To improve their jumping robot, researchers used a diffusion-based AI model that tested 500 design variations guided by an initial “embedding vector.” After selecting the top performers, they refined the vector over five rounds to generate better designs.

One final design, though blob-like in shape, was scaled to fit their robot and 3D-printed, resulting in improved jumping performance.

Jumping spiders and flying bees: The advancement in bio inspired microrobots

According to CSAIL’s Byungchul Kim, the key advantage of diffusion models is their ability to discover creative, unconventional design solutions.

“We wanted to make our machine jump higher, so we figured we could just make the links connecting its parts as thin as possible to make them light. However, such a thin structure can easily break if we just use 3D-printed material. Our diffusion model came up with a better idea by suggesting a unique shape that allowed the robot to store more energy before it jumped, without making the links too thin. This creativity helped us learn about the machine’s underlying physics.”

To make sure their jumping robot landed safely, the team asked their AI system to design a better foot. After several rounds of testing and refining, they chose the best-performing version and attached it to the robot.

The result? A big success—the robot with the AI-designed foot fell 84% less often than the standard model.

This shows that AI tools like diffusion models don’t just help with jumping—they can also improve balance, stability, and design quality in all kinds of robots. From factory machines to home assistants, this approach could help engineers build better bots faster, with less trial and error.

To build a robot that both jumps high and lands safely, researchers trained an AI system to balance the two goals using numerical data. It learned how to design shapes that optimized both height and landing stability.

The current robot, made from 3D-printable materials, already outperforms human designs. But the team believes it could jump even higher with lighter materials in the future.

MIT CSAIL’s Johnson Wang sees this as just the beginning. He imagines a future where you could simply describe a robot in everyday language, like “build one that picks up a mug”—and AI would generate the design.

Kim adds that the AI could also explore how robot parts connect and move, helping build smarter machines. They’re even looking into adding more motors to better control jumping direction and landings.

Journal Reference:

Byungchul Kim, Tsun-Hsuan Wang, and Daniela Rus. Generative-AI-Driven Jumping Robot Design Using Diffusion Models. Paper